ABOUT US —

cnc cutting and engraving

laser. plasma. router.

At M&N Engineering, we design, cut, fabricate and install CNC cut building additions in Accra, Ghana, using metal and non-metal materials. We also cut and fabricate machine parts (sprockets, gears, brackets, footings etc) using laser, plasma or CNC routing. We do not achieve speed at the expense of quality. Expect super clean edges, tight tolerances and a beautifully-crafted finished product.

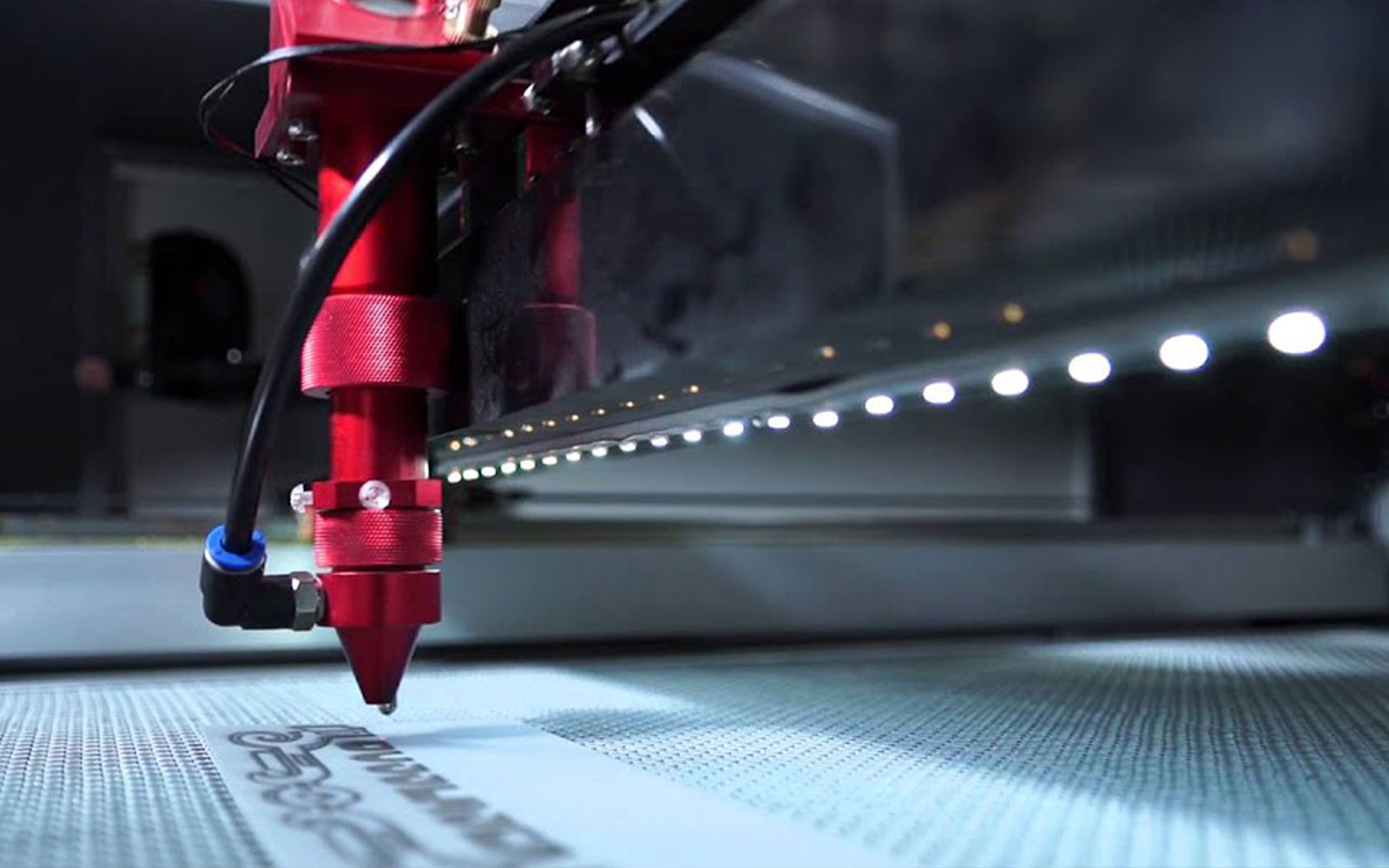

01 —

cnc laser cutting

A continuous cut is produced by moving a CO₂, YAG, or fiber powered laser cutting head over the work piece with the use of a CNC gantry system. Laser cutting is great for production quantity and quality parts since the cutting process is quite fast and precise.

Strength: Excellent cut edge quality & can cut a wide variety of materials.

Weakness: More expensive than plasma cutting & not capable of cutting thick metals.

Related Materials: Steel, Aluminum, Stainless Steel, Plywood, & Acrylic.

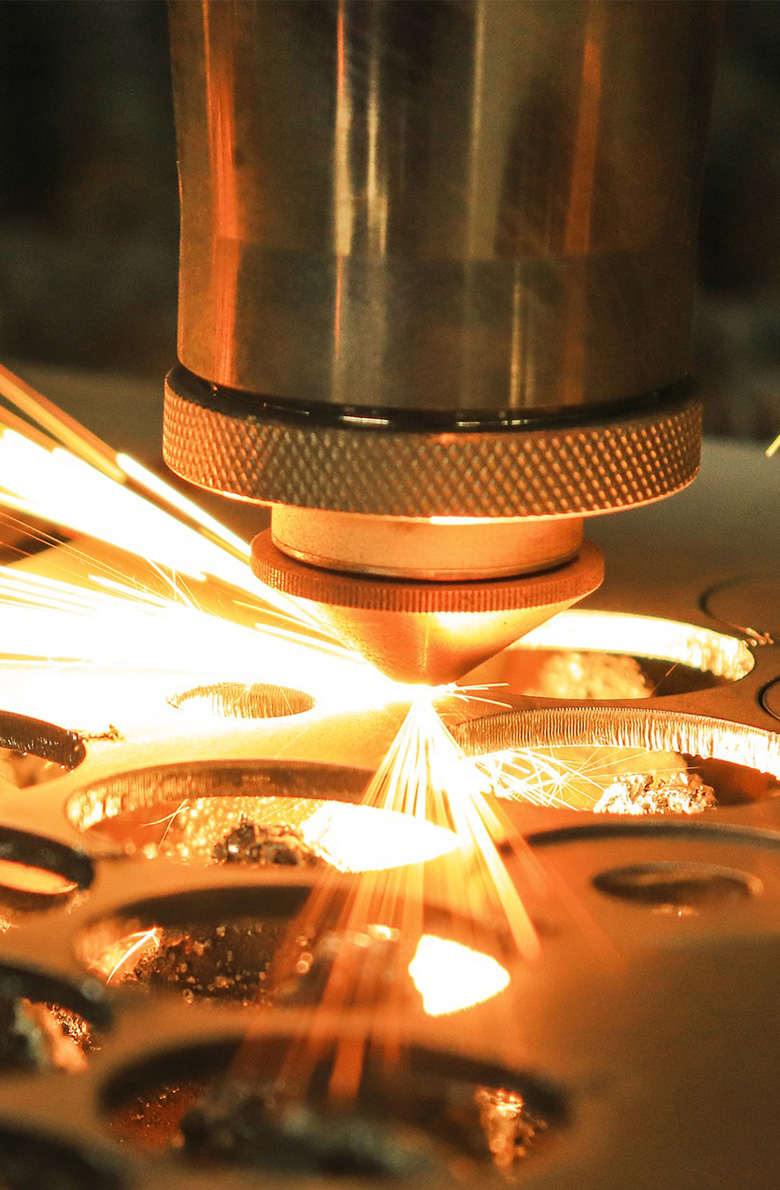

02 —

cnc plasma cutting

When prototyping quickly and on a budget, CNC plasma cutting is the best option. Cuts can be made in a wide array of materials, including stainless steel, aluminium, mild steel, and more. The speed of plasma cutting also makes it ideal for large pieces, extended jobs, and production run parts.

Strength: Most affordable cutting method with quick processing times.

Weakness: Less accuracy compared to laser or waterjet & larger heat affected zone.

Related Materials: Steel, Aluminum, Stainless Steel, Brass, & Copper.